what are you looking for?

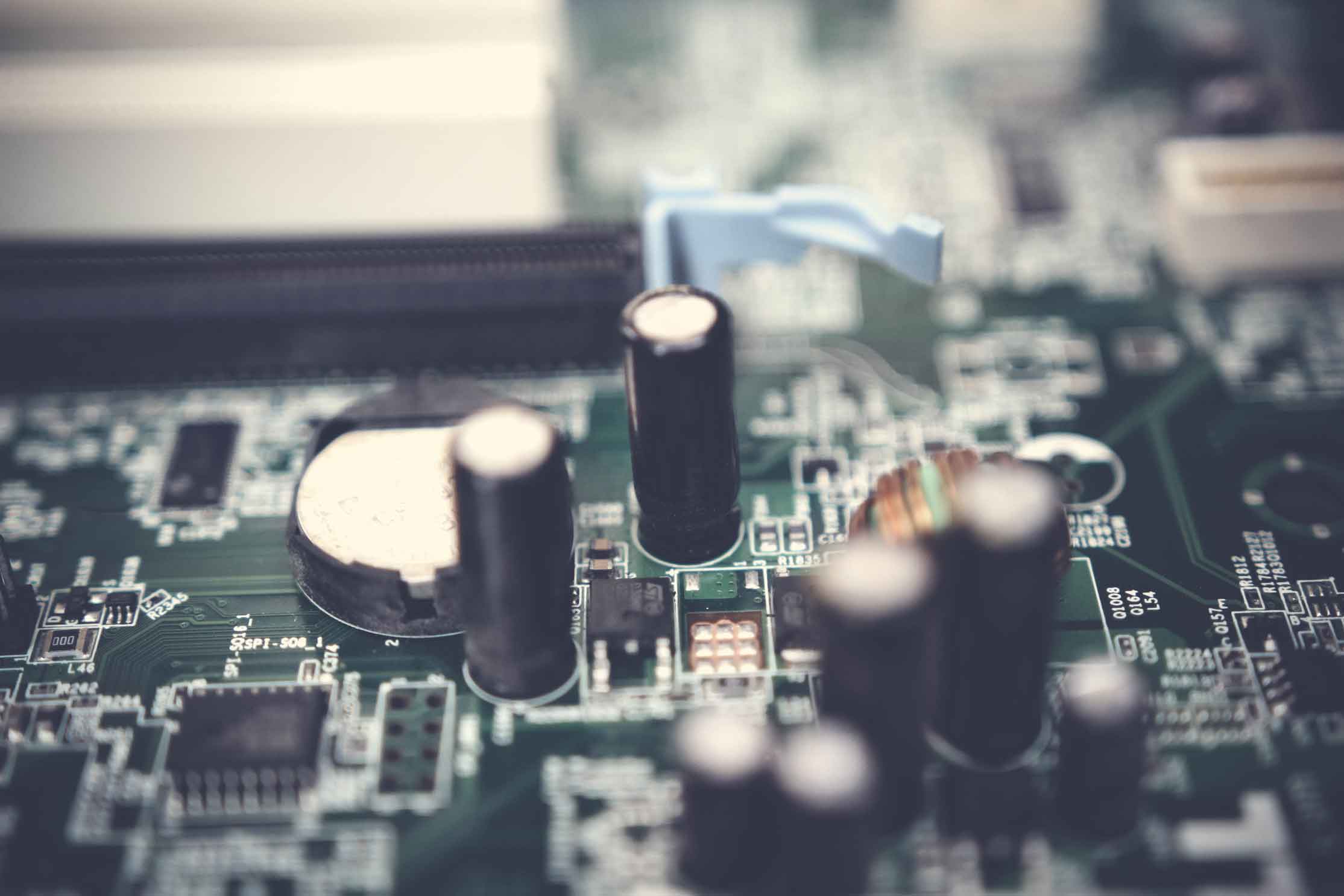

How to choose desiccant for electronic components

How to choose desiccant for electronic components

How to double the effectiveness of container desiccant?

How to double the effectiveness of container desiccant?

How shall we do about wine packaging mildew and moisture?

How shall we do about wine packaging mildew and moisture?