In recent years, the problem of moldy shoes in foreign trade has remained high, although many factories have taken various measures to prevent mold, but according to incomplete statistics from the customs department, in 2006, the annual export of single footwear reached 10 billion pairs. At the same time because of mold, according to preliminary statistics from the Ministry of Commerce: in 2006, 9.8% of China's finished shoes were rejected by foreign customers because of mold, resulting in a direct economic loss of US$2.98 billion. In addition, statistics show that in recent years, the loss of export products also brought about by 3.6% in the speed of rapid growth, a whole cabinet of products were destroyed, rejected or even claims, so that the factory to suffer.

Picture from internet

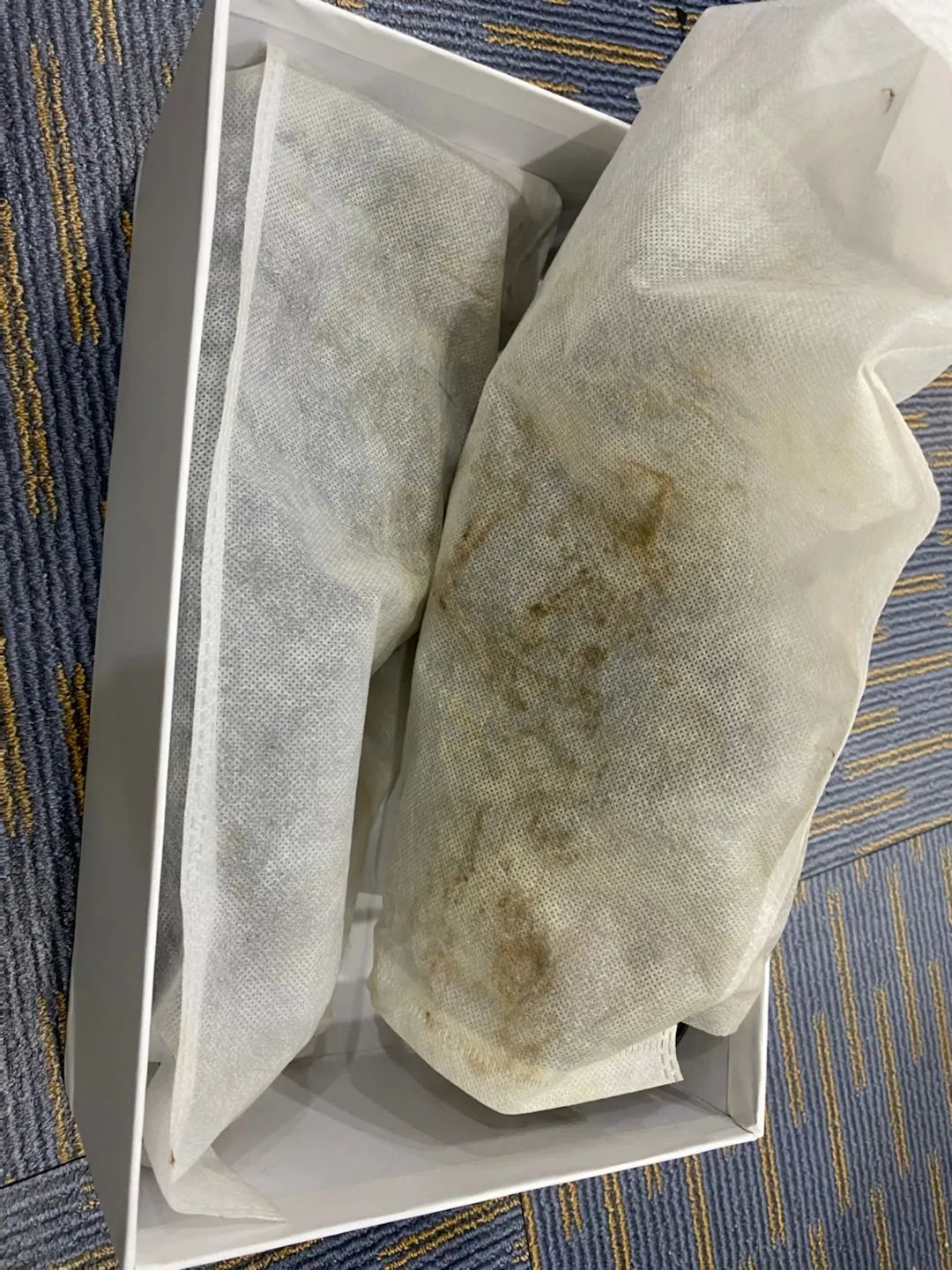

After a series of observations of moldy shoes, we found that foreign trade shoes moldy, the main moldy parts are more concentrated in the needlework stitching, glue bonding, then it is exactly which link is wrong, resulting in foreign trade shoes and clothing moldy?

At the same time, 206 large and medium-sized shoe factories, 83 furniture factories, 47 handbag factories tracking survey, and respectively from the factory material procurement to cutting, sewing, (shaping) packaging, storage, transportation after in-depth investigation of various aspects, came up with an unexpected result, 46.8% of the mould is caused by the glue of the lamination, 23.2% of the mold is caused by the packaging, 13.5% of the reasons, only 16.5% were caused by unclean materials themselves.

This is the main reason why foreign trade footwear is repeatedly plagued by mildew.

Why is glue the culprit of mold?

Picture from internet

Picture from internet

First of all, the general glue is composed of polyvinyl alcohol, white latex, sodium stearate, talc, urea, ethylene glycol, sucrose, flavours, water, etc. It is slightly irritating, volatile and the volatile gas has weak tear-destroying properties. To eliminate the irritating smell in the glue, the glue manufacturer will add a small amount of ammonia to the glue to balance the odour. But at the same time, the alkaline environment makes the glue, especially the water-based white emulsion glue rich in sugar and protein, provides a lot of nutrition and food for mold to breed.

Secondly, the Pearl River Delta and Yangtze River Delta regions have a subtropical climate and are transported by sea, with great variations in temperature and humidity, increasing the risk of moisture and mold in the glue.

How to solve the mold of glue?

Picture from internet

Picture from internet

The American Society for Testing and Materials (ASTM) pointed out that in order to solve the problem of moldy glue, American researchers will glue 10G with Pγ radiation amplitude, it will be placed at 30 ℃, relative humidity of 80% of the environment storage 360 days, the mold did not multiply; and unradiated glue, in the same conditions and the same time after storage mould, amplitude feed can achieve sterilization effect , can be stored for a long time without deterioration. However, the effects of long-term use of irradiated glue on humans and animals are unknown.

So, how do we prevent mold from glue?

Anti-mold experts tell you that Anti-mold agent is the most direct way of anti-mold for shoes, but also more general anti-mould products, for PU shoes, fur-tipped shoes, brushed leather shoes, sheep game leather shoes, and such boots, outdoor shoes, hiking shoes, snow boots these materials due to heavy grease or increasingly environmentally friendly conditions, extremely easy to mold.

Picture from internet

Picture from internet

If you would like a more comprehensive assessment of the risk of mold, you can cut a sample and send it to our microbiology laboratory to help you assess the risk of mould and the type of old free of charge, to see if the efficacy of the shoe anti-mold agent can inhibit the species of the material or not.