what are you looking for?

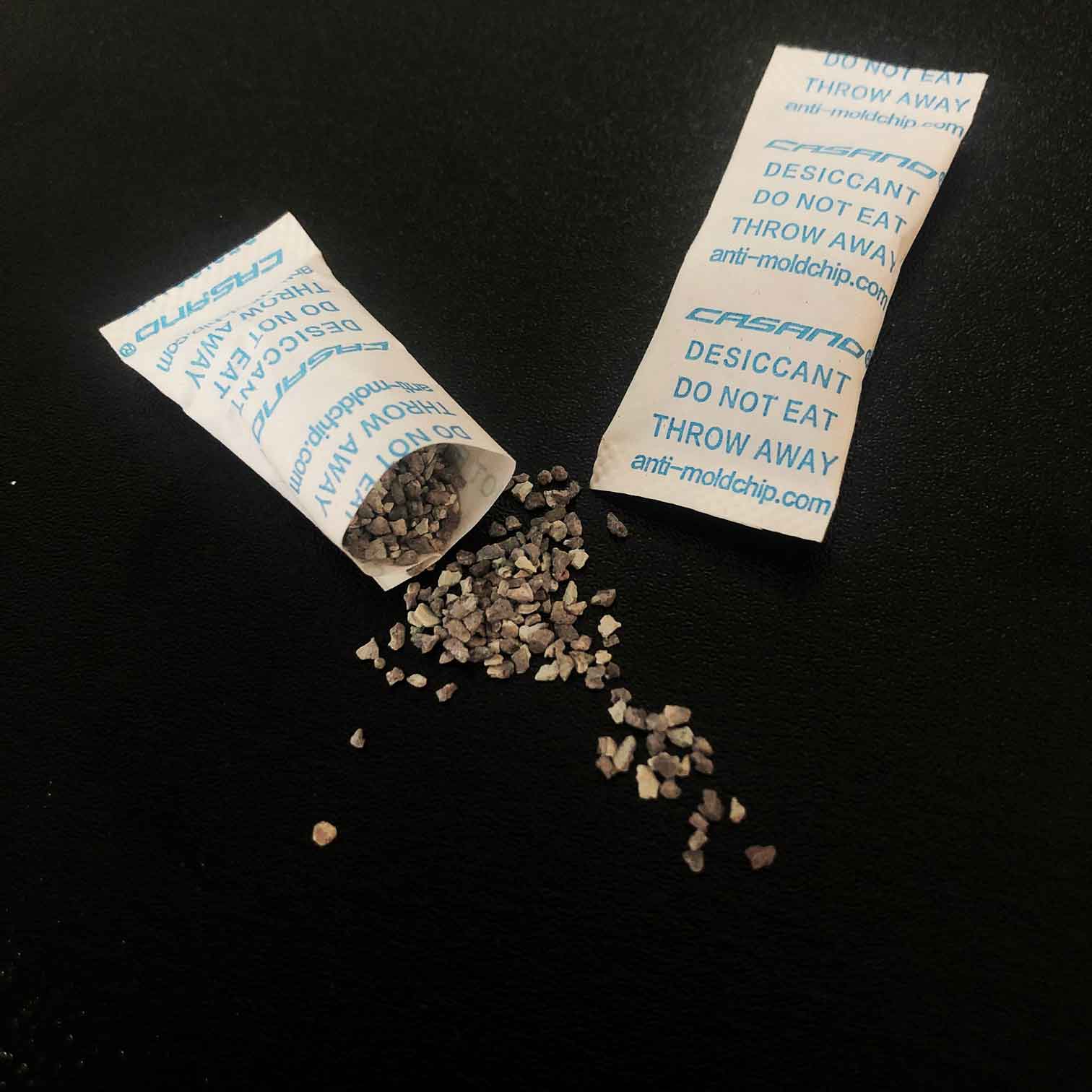

How to judge the quality of industrial desiccant

How to judge the quality of industrial desiccant

How to deal with the rainy season

How to deal with the rainy season

Why it's important to protect your garments from moisture

Why it's important to protect your garments from moisture

How to effectively avoid moisture in furniture?

How to effectively avoid moisture in furniture?